The future development of wire and cable will focus on quality and innovation

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2021-03-19 17:04

- Views:

The future development of wire and cable will focus on quality and innovation

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2021-03-19 17:04

- Views:

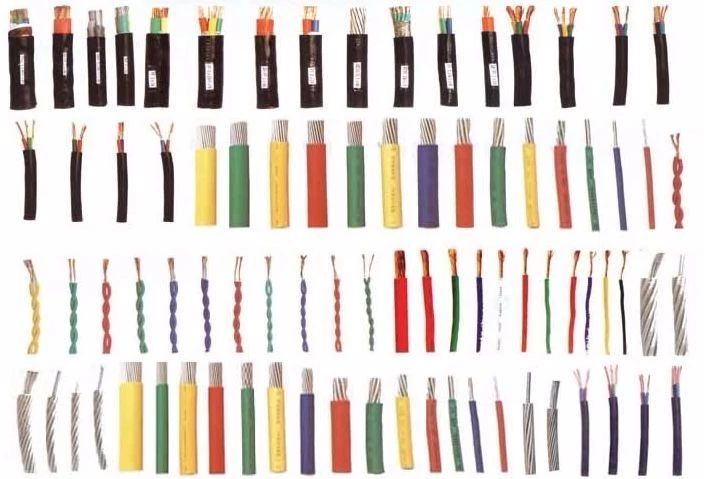

The wire

With the development of China's electric power industry, the requirements for supporting industries are becoming higher and higher. As an important part of the electric power supporting industry, electric wires and cables are also no exception, facing the need of upgrading to meet the needs of China's electric power development. The future wire and cable enterprises should improve technology, save raw materials, develop new environmental protection materials and so on.

The development of wire and cable industry has promoted the development of power transmission and distribution, electric energy transmission and other industries. With the development of China's power, data communication, urban rail transit and other industries, the demand for wire and cable products has increased, which has promoted the improvement of the scale of the industry. In the future, the development of wire and cable industry technology mainly involves the following aspects.

1. The development of carbon fiber is getting faster and faster in recent years. One possibility is that carbon fiber cable may replace the traditional steel-cored aluminum stranded wire in the future. Carbon fiber cable is an alternative product of traditional steel-cored aluminum stranded wire (bare wire), which is mainly used in 110kV ~ 220kV lines. Compared with the conventional steel-cored aluminum conductor (ACSR), the ACCC's aluminum cross-sectional area increases by 29%, while the weight per unit length is 20% lighter. Therefore, under the condition of a certain allowable drape, the ACCC can greatly improve the transmission capacity of the line and reduce the loss. Cable enterprises can replace a large number of ordinary conductors with ACCC conductors, and realize the capacity expansion of the power grid without adding new lines, greatly saving land, tower and engineering costs, and in line with the policy direction of energy conservation and efficiency. Carbon fiber composite wires will be a revolutionary replacement for existing wires. Therefore, it provides a new development opportunity for those enterprises which have strong competitive advantage in the field of carbon fiber composite wires.

2. High temperature superconductivity technology will get great development in the future. Due to the advantages of low price, large capacity, low loss and no electromagnetic pollution, high temperature superconducting cable has attracted much attention in the world, and many countries have raised the development of superconducting industry to a strategic height. China has made a major breakthrough in high-temperature superconductivity technology.

At the same time, on the basis of high-temperature cables, the relevant national plans also set up to support the "high-temperature superconducting power transmission" major projects. At present, China imports about 2 billion yuan of high-temperature cables from abroad every year for domestic construction. It is estimated that the global superconducting application market will reach 244 billion dollars (about 1486.9 billion yuan) by 2020, and high-temperature superconducting cables account for about 5% of the market share. Therefore, the research and development and application of high temperature superconductivity technology will be an important technology in the wire and cable industry in the future.

3, aluminum rare earth optimization treatment technology will be greatly developed. The production of electrician aluminum rod by continuous casting and rolling process is very popular in China and has good performance. But the equipment is still stuck in the early 1970s level, there is no big innovation on technology. To actively promote our country unique rare earth aluminum optimization technology, special equipment and technology and the introduction of some key adding aluminium zirconium alloys, the molten aluminum coal-fired furnace into molten aluminum fuel oil or natural gas furnace, eliminating molten aluminum coal-fired furnace coal dust and smoke emissions, and set up the flue gas purifying flue gas filtering device, improve the quality of emissions, increase yield, reduce cost, at the same time make the operating temperature of the conductor from 70 ℃ to 150 ℃, carrying capacity increased by 1.6 times.

Aluminum substituted copper technology has been proposed for many years, and has been widely used in Europe and the United States and other countries. It is not widely used in Asia, but in recent years, many Chinese wire and cable enterprises have begun to try aluminum substituted copper. American general cable has even worked out a set of aluminum alloy cable standard system with Shanghai wire and cable research institute. Compared with aluminum, copper has better electrical conductivity and thermal conductivity, and can reduce the loss of electric energy in the transmission of current, so it has been difficult to cut and shed by wire and cable manufacturers. At present, more than 60% of China's wire and cable industry are made of copper cables. Due to the relative shortage of copper resources, the proven copper resources in China have been deeply or even overexploited.

The conductivity of aluminium alloy cables with copper cable, its flexibility, compared with copper cable, changed the past pure aluminium cable poor mechanical strength, low ability to resist fatigue, tapping are prone to accidents, ensure the cable in the case of long time overload and overheating the continued stability of the cable connection, also makes up for the traditional copper cable has memory effect and high rebound performance, reduce the line loss. Besides, no matter from raw material production, processing and fabrication to the transportation, installation, operation, recovery, a variety of ways, aluminum alloy cable compared with the traditional copper cable, has the incomparable economic and environmental advantages, there is no doubt that will be the perfect replacement for copper wire, this material for heavy industry light wire and cable enterprise is actually a good thing, at least to reduce the demand for money, you know China is a little copper production country, basic imports of copper, and it is a major aluminum producers. Not only that, but aluminium prices are much lower than copper prices, which is good for reducing the need for capital.

cable

4. With the emergence of environmental pollution such as smog, people nowadays pay more and more attention to environmental protection, and the wire and cable industry is no exception, which is bound to face the requirements for environmental protection. The environmental protection of wire and cable industry mainly refers to the material environmental protection. At present, the production of wire and cable a large number of rubber, polyvinyl chloride, polyethylene and other polymer chemical materials. In the process of production, a large number of poisonous and harmful gases are produced. Therefore, we should actively develop environment-friendly materials and produce environment-friendly wires and cables. Japan's Fujikura and other cable companies in the development of environmentally friendly wire and cable, in order to monopolize the market, and actively promote the government to issue environmentally friendly wire and cable product standards. In recent years, the sales share of environmental protection wires and cables has expanded sharply, and ordinary wires and cables and flame retardant wires and cables cannot compete with them at all. In addition, in the wire and cable production process of the leftover material, can be directly recycled.

5. From the point of view of the installation of wire and cable, it is also facing a new development trend, that is, thin sheath and miniaturized section. In view of the convenience of installation, use and transportation, while reducing the cost of raw materials as much as possible, wire and cable products have a tendency of development, that is, the cable is developed into a thinner sheath, a smaller section, and at the same time to ensure the flow carrying capacity. In contrast to the previous types, this requires a comprehensive wire and cable industry technology

Dongguan NewTopp Electrical Machinery Co.,Ltd.

No. 286, Huaide Avenue, Humen Town, Dongguan City, Guangdong Province

Phone: +86-769-85372062/3

Dongguan NewTop-IOT Technology Co.,Ltd.

Dongguan NewTop-IOT Technology CO.,LTD

Address: No. 286, Huaide Avenue, Humen Town, Dongguan City, Guangdong Province Phone: +86-769-81886936 Fax: +86-769-81886936 Web: www.newtopiot.com |

Jiangsu NewTopp Precision Machinery Co.,Ltd.

Jiangsu NewTopp Precision Machinery Co.,Ltd.

Address: No. 168, Haitai Road, Dongtai City, Jiangsu Province Phone: +86-515-85108601 Fax: +86-515-85108606 Web: www.sjnewtopp.com |

NewTopp Machinery International Co., Ltd.

NewTopp Mechanical Int’L CO.,LIMITED

Address: Room 04, 7th Floor, Kaitu Development Building, 33 Mongkok Road, Kowloon, Hong Kong Phone: 00852-27935511 Fax: 00852-35902333 |

Copyright © 2021 Dongguan NewTopp Electrical Machinery Co.,Ltd. All Rights Reserved 粤ICP备10003388号-2

By: www.300.cn